Who is responsible for de-energizing electrical equipment and services? This question lies at the heart of ensuring safety and compliance in electrical work. Understanding the roles and responsibilities of personnel involved in de-energizing tasks is paramount to prevent accidents, protect equipment, and maintain a safe working environment.

Proper training, certification, and adherence to established procedures are essential for those performing de-energizing tasks. This article delves into the responsibilities, procedures, and safety considerations associated with de-energizing electrical equipment and services, providing a comprehensive guide for ensuring a safe and compliant work environment.

Who is Responsible for De-energizing Electrical Equipment and Services?

The responsibility for de-energizing electrical equipment and services falls upon qualified personnel who have undergone proper training and certification. These individuals must possess a thorough understanding of electrical safety protocols and procedures to ensure that de-energizing tasks are carried out safely and efficiently.

Typically, the following personnel are responsible for de-energizing electrical equipment and services:

- Licensed Electricians:Hold a valid electrician’s license and have received specialized training in electrical safety and de-energizing procedures.

- Qualified Electrical Workers:Have completed a recognized apprenticeship program and possess the necessary knowledge and skills to safely de-energize electrical equipment.

- Authorized Maintenance Personnel:Trained and certified by the organization to perform de-energizing tasks on specific electrical equipment.

In specific scenarios, the following individuals may also be responsible for de-energizing electrical equipment and services:

- Plant Operators:May be responsible for de-energizing equipment in industrial settings.

- Facility Managers:May oversee de-energizing tasks in commercial or residential buildings.

- Emergency Responders:May need to de-energize electrical equipment in emergency situations.

It is crucial that all personnel involved in de-energizing electrical equipment and services receive proper training and certification to ensure their safety and the safety of others.

Procedures and Protocols for De-energizing Electrical Equipment and Services

De-energizing electrical equipment and services involves a systematic approach to ensure safety and prevent accidents. The following procedures and protocols must be strictly followed:

- Identify the Equipment:Determine the specific electrical equipment or service that needs to be de-energized.

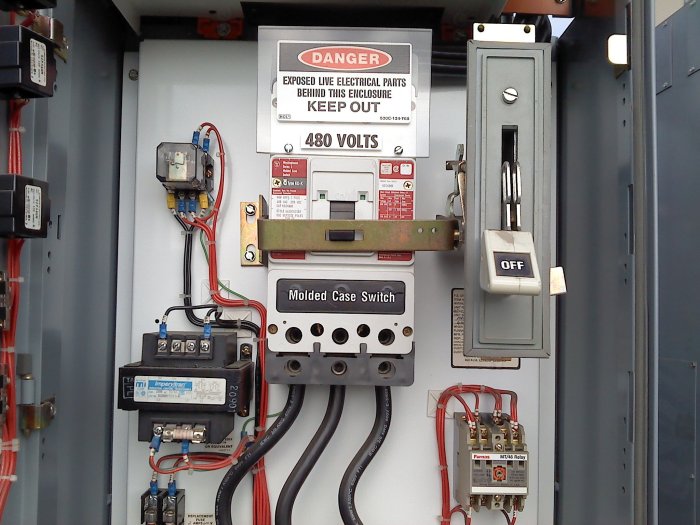

- Identify the Energy Source:Locate the source of electrical power for the equipment, such as a circuit breaker, fuse, or disconnect switch.

- Isolate the Equipment:Open the circuit breaker, pull the fuse, or operate the disconnect switch to isolate the equipment from the energy source.

- Lockout/Tagout:Apply lockout/tagout devices to the energy source to prevent accidental re-energization.

- Verify De-energization:Use a voltage tester or other appropriate method to verify that the equipment is de-energized.

- Ground the Equipment (if necessary):In some cases, it may be necessary to ground the equipment to dissipate any residual electrical energy.

Different methods can be used for de-energizing electrical equipment, depending on the type of equipment and the available resources. These methods include:

- Manual Switches:Used to manually open or close a circuit, isolating the equipment from the energy source.

- Circuit Breakers:Automatically trip when an overload or fault occurs, interrupting the flow of electricity.

- Fuses:Designed to melt and break the circuit when an excessive current flows, protecting the equipment from damage.

Safety Considerations for De-energizing Electrical Equipment and Services: Who Is Responsible For De-energizing Electrical Equipment And Services

De-energizing electrical equipment and services requires utmost attention to safety to prevent electrical shock, arc flash, and other hazards. The following safety considerations must be taken:

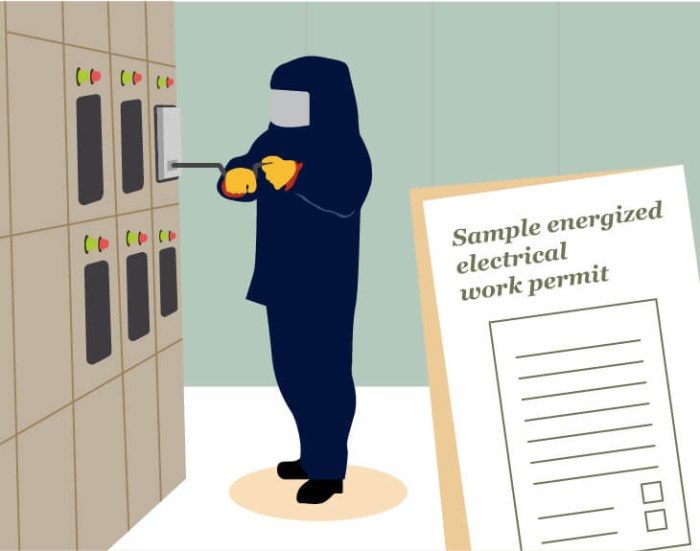

- Wear Appropriate PPE:Wear insulated gloves, safety glasses, and other personal protective equipment (PPE) to protect against electrical hazards.

- Follow Safety Protocols:Strictly adhere to established safety protocols and procedures for de-energizing electrical equipment.

- Identify Potential Hazards:Be aware of potential hazards such as live wires, energized equipment, and slippery surfaces.

- Use Proper Tools and Equipment:Utilize insulated tools and equipment specifically designed for electrical work.

- Avoid Contact with Live Wires:Never touch live wires or energized equipment, even if you are wearing PPE.

- Be Aware of Arc Flash Hazards:Wear appropriate arc flash PPE and follow proper procedures to prevent arc flash incidents.

By following these safety considerations, personnel can minimize the risks associated with de-energizing electrical equipment and services.

Documentation and Record-keeping for De-energizing Electrical Equipment and Services

Accurate documentation and record-keeping are essential for maintaining a safe and compliant electrical system. The following documentation should be maintained:

- Work Orders:Document the purpose, scope, and details of de-energizing activities.

- Permits:Obtain necessary permits or authorizations for de-energizing work.

- Lockout/Tagout Records:Maintain records of lockout/tagout devices used and the individuals responsible for their application and removal.

- Training Records:Keep records of training and certification for personnel involved in de-energizing activities.

Maintaining proper documentation and records ensures compliance with regulatory requirements and provides a historical record of de-energizing activities for future reference and audits.

FAQ Section

Who is typically responsible for de-energizing electrical equipment?

Qualified electricians or authorized personnel who have received proper training and certification.

What are the potential hazards associated with de-energizing electrical equipment?

Electrical shock, arc flash, equipment damage, and explosions.

What is the purpose of lockout/tagout devices?

To prevent accidental energization of equipment during maintenance or repairs.